Surface Finishes

Surface Finishes

High-quality surface finishing services improve your part’s aesthetics and functions regardless of the manufacturing process used. Deliver quality metal, composites, and plastic finishing services so you can bring the prototype or part you dream of to life.

Our Portfolio of Surface Finishing

Our part finishing services are exceptional as our teams are experts in plastic, composite, and metal surface finishing. Furthermore, we have state-of-the-art machines and infrastructure to bring your idea to life.

As machined

Bead blasting

Anodizing

Electroplating

Polishing

Powder Coating

Our Surface Finishing Specifications

Part surfacing finishing techniques can either be for functional or aesthetic purposes. Each technique has requirements, such as materials, color, texture, and price. Below are the specifications of the plastic finishing techniques rendered by us.

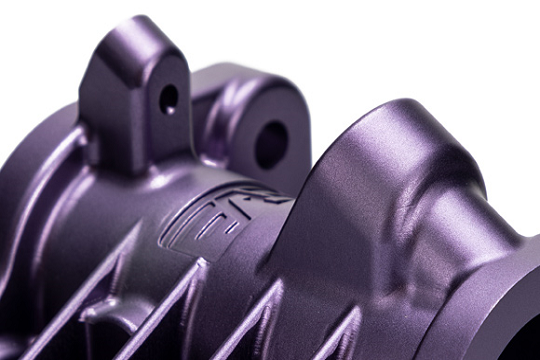

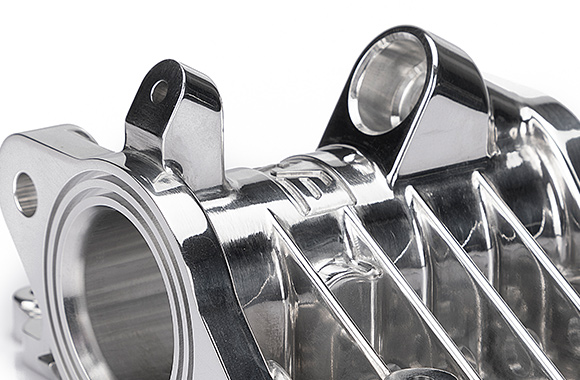

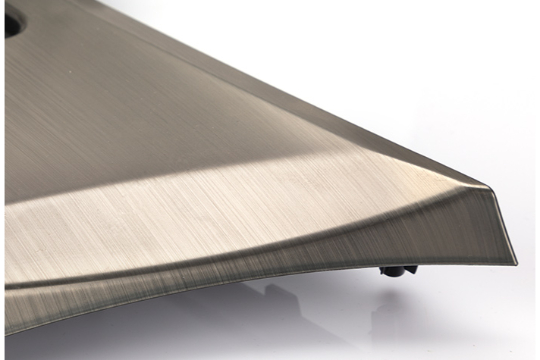

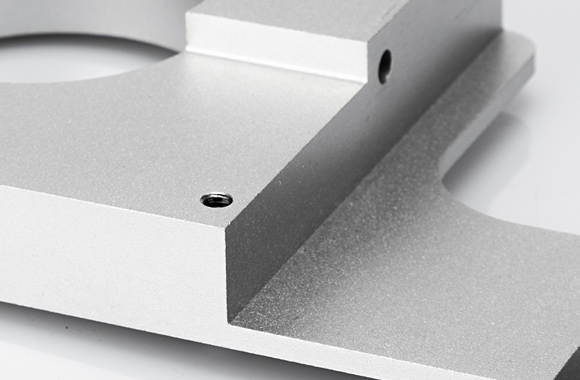

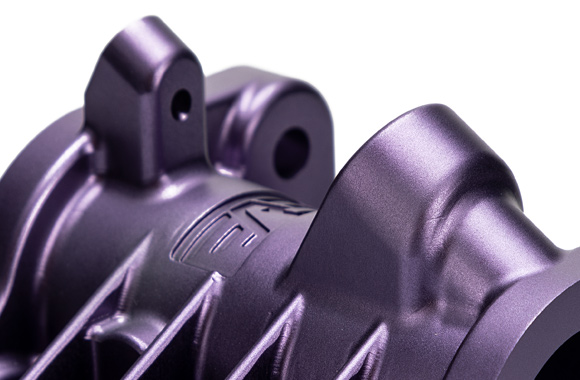

Gallery of Parts With Cosmetic Surface Finish

Get a feel of our quality-focused custom parts made using precision surface finishing techniques.

See What Our Customers Say About Us

A customer’s words have a more substantial impact than a company’s claims – and see what our satisfied customers have said regarding how we fulfilled their requirements.

The demanding requirement of the automotive industry requires strict adherence to high tolerance standards. cncjsd understands all of these requirements and has provided top-notch polishing services to us for the past decade. These products can withstand various environmental conditions and stay durable for a very long time.

Hi Henry, on behalf of our company, I want to acknowledge the superb quality work we continuously get from cncjsd. The chrome plating quality we got from your company far exceeds our expectations compared to other companies we worked with in the past. We will surely come back for more projects.

I contacted cncjsd for our anodizing needs, and they were confident they could provide the best solution. From the ordering process, it was clear that this company was different from any other metal finishing companies we had ever used. Although the product was in large volume, cncjsd completed the finishing perfectly within a short time. Thanks for your service!

Work With Various Industrial Applications

We have been developing a number of rapid prototypes and low-volume production orders for customers in multiple industries ranging from automotive, aerospace, consumer goods, medical devices, robotics, and more.